Looking for an alternative, sustainable way of practicing architecture? Apply now for our Postgraduate!

jQuery(function() { _initLayerSlider( ‘#layerslider_20_1ru79di5pqdhq’, {createdWith: ‘6.11.2’, sliderVersion: ‘6.11.2’, skin: ‘v6’, navPrevNext: false, hoverPrevNext: false, navStartStop: false, navButtons: false, showCircleTimer: false, skinsPath: ‘https://criticalconcrete.com/wp-content/plugins/LayerSlider/assets/static/layerslider/skins/’}); });

Concrete, as the most used building material worldwide has a huge impact on our cities, societies and environment. Much of our research is based on the idea to create an alternative solution for conventional methods of building, such as building with concrete. In this article, we will tackle basic and relevant knowledge and information about concrete, to understand why it is important to think about alternative solutions for the future of our building habits. This write-up will be part of a series of small papers related to meaningful knowledge, to understand why it’s urgent to rethink our conventional building approaches.

Concrete, cement & mortar – definitions

To give a brief overview of what we are talking about in specific, we will first define the most important terminologies that we will need to understand the whole topic around concrete.

Four important terms you should know about and understand their exact definitions:

Typical composition of concrete

cement // səˈment

Cement is the key ingredient to mix concrete. This product is mainly made out of crushed limestone mixed with shales and slates, shredded to a fine powder and heated up to approximately 1450°C. The heat causes a chemical reaction, also known as calcination.[1] That reaction along with the heating process causes a high amount of carbon-dioxide emissions, which makes cement production a big driver of greenhouse gas emissions. The entire process happens in a giant mixer, called a cement kiln. [2] The most popular kind of cement is portland cement, developed in England in the early 19th century. [3]

concrete // ˈkänˌkrēt

Concrete is an artificial building material, which consists of a binding agent like cement or lime, in addition to water and aggregates (sand and gravel) as well as potential additives (like fly ash or plasticizers). The cementitious part gets liquified with water. By adding water to the cement a chemical reaction is caused and the process of crystallization begins. In the next step some additives such as gravel and sand are added. These aggregates are held together by the liquified cement. Once the whole mixture is cured, this process will finish with a solidified product, called concrete.

mortar // ˈmôrdər

Mortar is a workable paste, used to bind bricks, stones or to fill gaps and holes. The basis is made out of a binding agent (such as slaked lime, ash or, most commonly nowadays, cement) added with water and a fine aggregate, mainly sand.

Mortar is one of the oldest building materials, used for many thousand years. For a long time, slaked lime, volcanic ashes or clay worked as a binding agent. During the nineteenth century portland cement was invented. From that time cementitious mortar rose in popularity and replaced the old binding products.

These two kinds of mortar differ in two ways. On the one hand cementitious mortars usually are more workable due to faster curing, higher water resistance and less cracking, on the other hand non-cementitious mortars significantly cut greenhouse emissions while processing. It even can absorb CO2, which appears to happen when lime mortar cracks, so that air (especially CO2) can be absorbed. By absorbing CO2, lime mortar is even molding and gets even stronger.[4] To put it plainly: it’s an environmentally friendly and more sustainable alternative.

reinforced concrete // ˈˌrēinˈfôrst ˈkänˌkrēt

In most cases concrete is combined with steel rebars, to compensate for the low tensile strength. The capability of concrete to react on compressive load is ten times bigger than the capability to bear tension loads.[5]

A more advanced and further developed version of conventionally reinforced concrete is prestressed concrete. To make concrete structures more durable against tensile forces, tendons, a high performing kind of rebar gets tensioned. Mainly these tendons are wires or threaded rebars. When applying in the casted concrete, the concrete part gets compressed, which gives the structure a higher performance, while being in service. [6]

Why is cement concrete so popular?

There are many reasons for its popularity: its liquid stone characteristics were revolutionary and created the possibility to make nearly every form out of concrete.

Cement concrete structures can be segmented and precast, making it suitable for big construction projects; and once solidified, it is a very strong material with the ability to bear high amounts of load. Designers adopted the versatile material, and nowadays we find furniture and accessories made of this material, in every kind of shape.

The use of concrete can be dated back to the ancient times. Romans mastered the use of hydraulic lime as a binding agent, called “opus caementicium”. After the fall of the Roman empire, the use of concrete faded, till it got resurrected in the early 19th century. Instead of using hydraulic lime, portland cement, a further development of the ancient version, was invented and led to a big rise in popularity of concrete in building industries. The first buildings during this time were bridges, foundations and harbours, facilitated by the compressive strength and workability of the new material.[7]

In the late 19th century iron rods, and later steel rebars, were added to poured concrete to increase tensile strength. It was mainly developed by the French Joseph Monier [8] – an invention which is ubiquitous in building industries nowadays. This invention led to a big rise in popularity in the residential and social housing sector. In comparison to conventional houses in those days, new concrete based housing projects were more durable, termite and fire resistant. The workability of concrete made it fast and easy to use on site. Pre-castable and serial development of construction elements cut costs significantly. In the 50s of the last century, concrete played a major role in evolving the architectural style of Brutalism, a socio-aesthetically driven architecture movement of showing raw, honest constructions often used for big scale civic and public projects. This architectural style was a dominating force during the next two decades. [9]

In addition, the raw materials of concrete are available in large quantities around the globe, which makes concrete cheap to produce. Limestone, sand and gravel are quite cheap. The main processing costs are caused by the cement production.

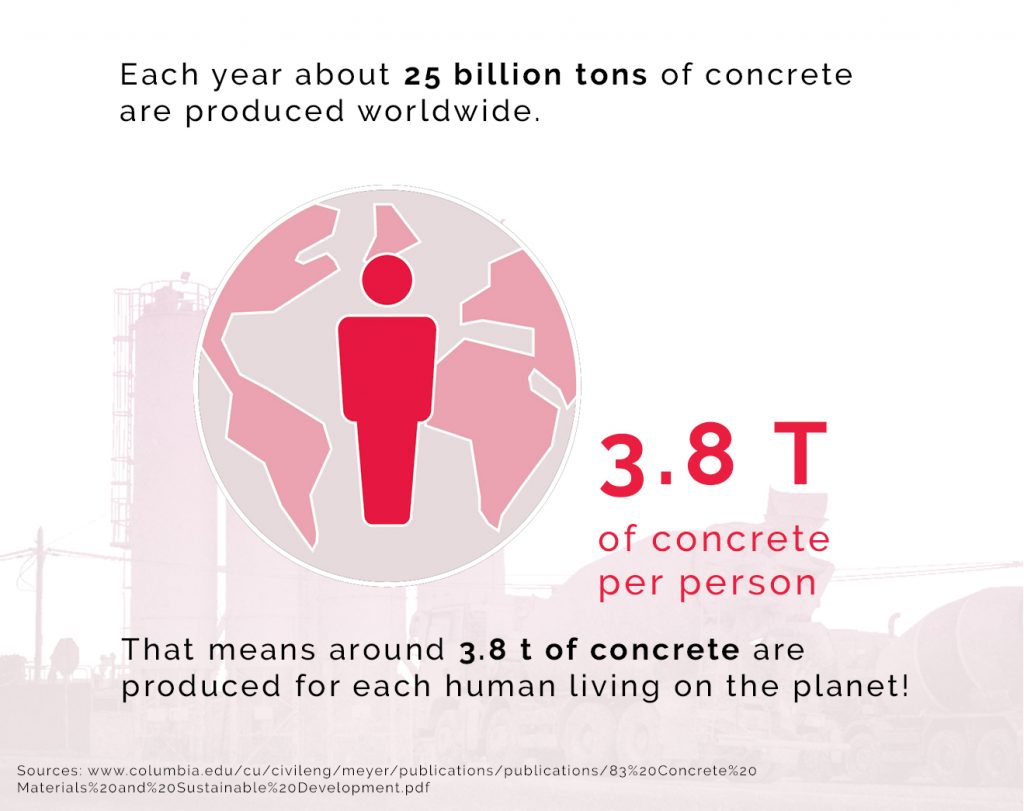

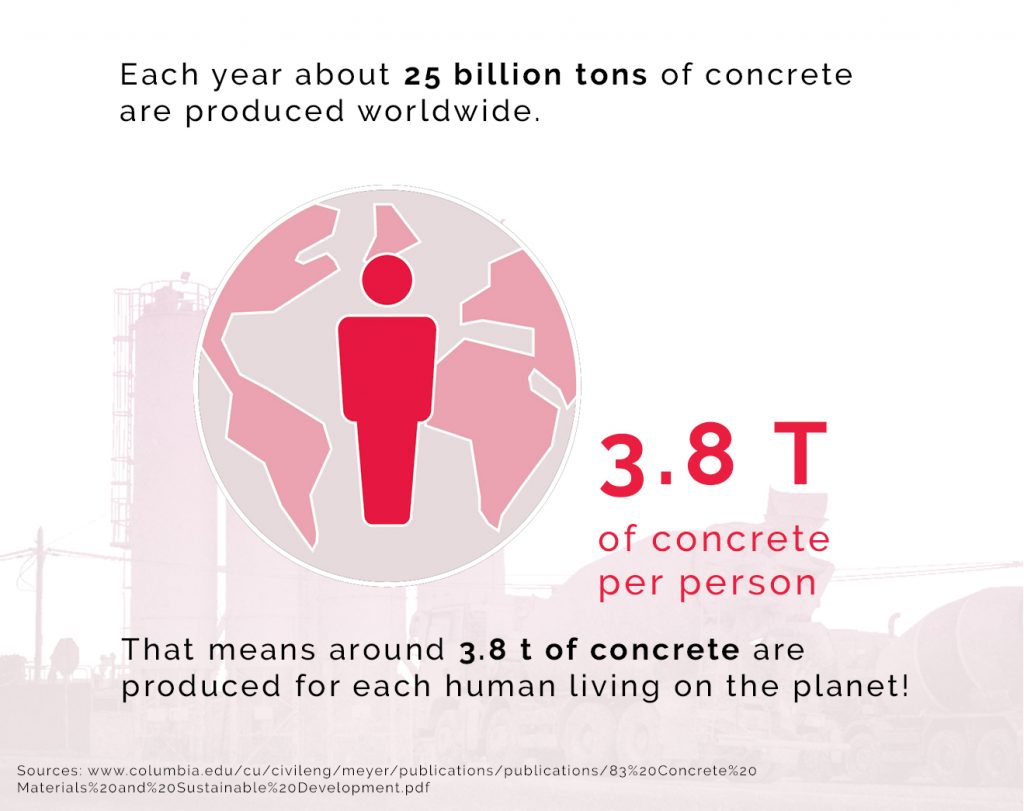

What quantity of resources are needed to produce cement concrete?

There are four main components of cement concrete (cement, water, sand and gravel). For reinforced concrete, there is an additional component – steel. Besides these materials, there are more raw resources needed to produce the main ingredients. To produce one tonne of cement, approximately two tonnes of raw limestone are necessary. [10] The production of cement is a high energy consuming process. One ton of cement takes about 120 kWh of energy in process heating. This energy is mainly obtained from fossil fuels and burning waste. [11]

The cement concrete recipe

There are several different recipes for making concrete. The recipes mainly differ in the ratio of cement and the added aggregates. Concrete can be mixed with different ratios to get a higher load bearing capacity or to get a higher ability to withstand different exposures, such as seawater, moisture or frost.

The following recipes just give you a basic overview about how a classic mixture of concrete could look like:

A standard concrete mix consists of 1 part water (7,7%), 2 parts cement (15,4%) , 4 parts sand (30,7%) and 6 parts gravel (46,1%). [12]

The higher the load the more cement you’ll need (f.e. a concrete column, foundation needs 1 part water (11,1%), 2 parts cement (22,2%), 2 parts sand (22,2%) and 4 parts gravel (44,4%) ).

Around 70% of the built concrete constructions are reinforced with steel, so you would usually have to add a certain percentage of steel rebars to the produced concrete (60-80 kg/m3 of concrete).[13]

That means a ton of average concrete consists of:

77 kg of water (7,7%)154 kg of cement (15,4%)307 kg of sand (30,7%)461 kg of gravel (46,1%)

Components of 1 tonne of concrete

Where is concrete used?

The use of cement concrete has various fields of application in construction and design. Since it was developed in the early XIXth century as a powerful structural material, it can be found in several constructive elements. The constructive elements made out of concrete can be summed up in three main categories:

massive built horizontal and vertical load bearing elements such as foundations and walls, used for small to middle scale buildings, such as residential housing.filigree skeleton construction elements, such as pillars and beams, mainly found in high rise buildings and large scale commercial buildingsspecial construction elements for infrastructural and exceptional building typologies, such as bridges, tunnels, dams or bunkers.

Where is concrete useful?

Nowadays concrete is used in many different ways. All constructive elements can be made in concrete and in most cases they are realized with this material.

But is it really necessary to replace other common construction methods with concrete?

It makes sense to use concrete in constructions, where load bearing elements have to bear big compressive strengths. A high rise a few hundred meters high? A tunnel? A dam? For sure! – There are fields of application, where no other material performs as well as concrete but in many cases concrete is used in small scale projects, where it is unnecessary and over proportioned.

How sustainable is cement concrete?

Concrete is certainly one of the building materials which gives a nearly unlimited range of use. As mentioned before, there are many upsides to using concrete. But there are always two sides of the coin.

A general definition for sustainability is meeting the needs of the present without compromising the ability of future generations to meet their needs. Sustainability is often discussed in environmental terms. It can also be related to two other important topics: society and economy.

Obvious and hidden impacts on our environment

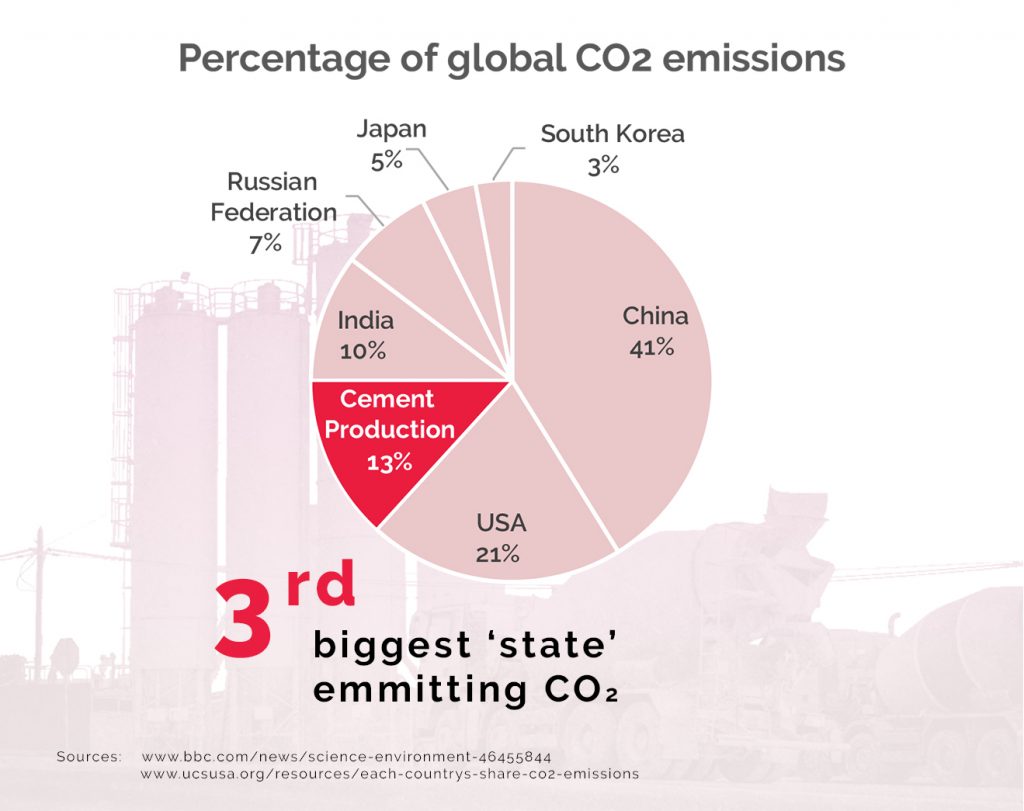

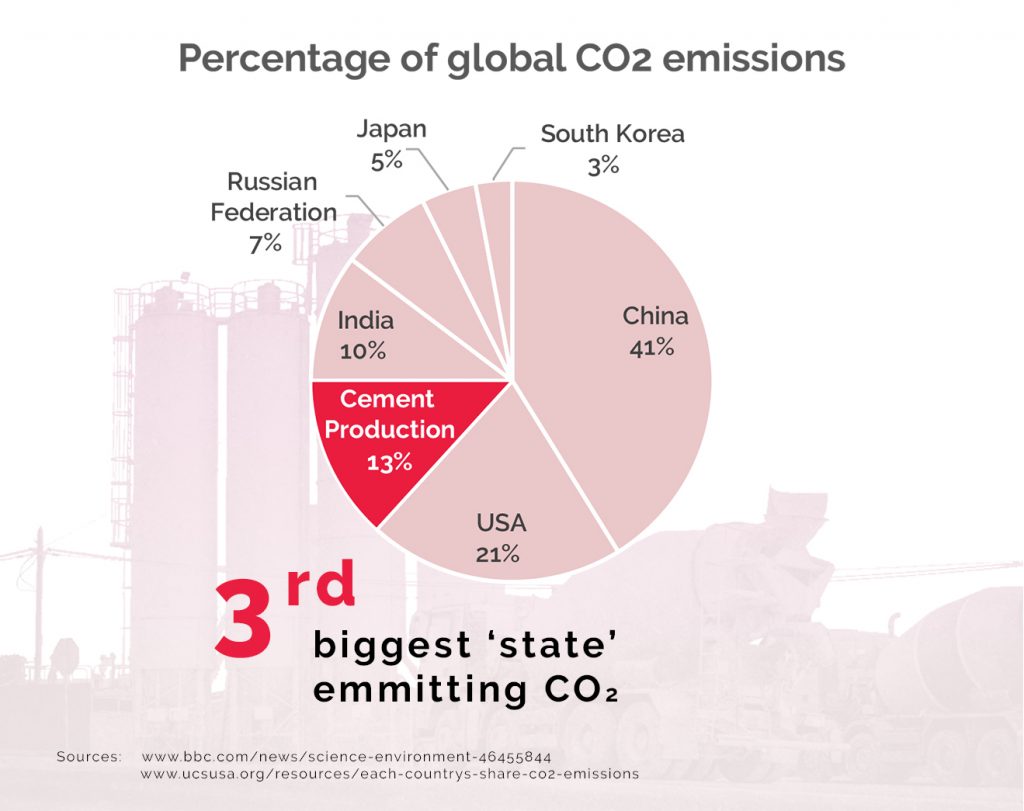

Pie chart comparison between countries CO2 emissions and cement production

The impact on our environment caused by the cement industry and by building with concrete is enormous. The production of cement is a high energy consuming process. This energy is mainly obtained from fossil fuels or burning waste [14] In addition the chemical process of producing cement releases one molecule of carbon-dioxide per each molecule of calcium silicate hydrate. For each ton of produced cement, one ton of CO2 is emitted just by chemically processing it [15] Besides the vast amount of carbon dioxide emitted, many other hazardous air pollutants such as NOX or PM10 are emitted during the process. [16]

Cement is just one part of concrete. The added aggregates, such as gravel and sand, are mined in humongous amounts to cover the demand of concrete industries. Many environmental systems are suffering from negative effects such as land loss by erosion, destruction of natural habitats, sealing and contamination of soil. Some of these aggregates, especially sand, have to be shipped around the world to service demands. [17] Just to give a short glimpse of one of the biggest cruxes in world of the concrete industries – new developing middle-east states, such as the United Arab Emirates or Qatar have to import big amounts of sand to service their huge demand in building industries, despite the fact that cities like Dubai or Qatar are located in the middle of sandy deserts. [18] However, not all of the sand we can find on the globe is suitable for concrete production; desert sand is too fine and round to be used as an aggregate. [19]

Furthermore, concrete production is a thirsty industry. It needs almost 10% of annual industrial water withdrawal, and 75% of the concrete production takes place in regions which are already facing water stress and drought. [20]

Beside this, the impact on society has to be emphasized. The internationalization of architecture and modern building technologies have a negative influence on vernacular building technologies and local architecture. New buildings tend to be built in a modern way with modern materials, such as concrete. Cost efficiency, the establishment of new building technologies and the time aspect are reasons for a significant decrease of traditionally built projects.

Impact of globalization and industrialisation on building traditions.

Comparison between the use of concrete and other building materials

One of the main issues caused by that situation is the loss of building knowledge and traditions. Traditional building techniques are being replaced by modern approaches. Around the world, houses and cities have been built according to local tradition for centuries. Now, knowledge that was gained in a long and enduring process is about to get lost in a few decades.

Main drivers for the loss of vernacular architecture are caused by the growing globalization and industrialization of the world. Innovations in building technologies can be spread easily around a fully connected world. Rare materials not locally available can be easily shipped from anywhere – and they get transferred in humongous amounts around the planet.

Downcycling cement concrete

The economic sustainability of concrete is always mentioned as a big pro. Nonetheless there are a few facts which are not properly taken into consideration. The production of concrete is cheap in comparison to other materials. A main reason for this, is that the aggregates you need to mix concrete are available in large quantities almost everywhere around the planet. But in recent times the local availability of certain components, such as sand are diminishing. [21] Our resources on the planet are finite, so using and monetizing resources as if they are infinite is unsustainable. To address this, the concrete industry tries to emphasize their product as recyclable, but to make it clear – concrete is not recyclableRecycling means, returning a material into a previous stage of a cyclic process. In case of the mentioned material, this is not completely possible. During calcination, the processing of the raw resource of limestone comes to a point of no return. Once cement is made, the process is irreversible. There is no commercially viable process to recycle it.[22] Recent reusing methods of concrete consist of shredding it and mainly using it as gritting material for infrastructural projects. In some cases this crushed concrete can be used as an aggregate to partly substitute gravel in concrete. Nevertheless these substitutes are small in numbers and in the end new concrete still requires additional water, cement, sand and gravel [23] Technically, the recent approaches to recycling concrete can be better named downcycling processes or a kind of mitigation. Many experts criticize the bigger potential of reusing shredded concrete for new concrete projects, [24] an effort which should be broadened in the future.

Contradictive durability of concrete structures

Many proponents often mention concretes’ durability as a big pro. The use of concrete without adding any other materials (such as rebars, made out of metal) technically creates a very durable building material. Despite, most of the applied concrete is reinforced to be able to react on tensile stress. But the application of reinforced concrete in terms of durability is a contradiction in terms. Here nature inevitably can shorten the life span of buildings built out of reinforced concrete. Due to different thermal expansions and the inevitable inheritation of oxidation of the used steel rebars, concrete constructions suffer fast deterioration during their lifespan. Recent studies have shown that there is a 50% chance of reinforced concrete structures to not fulfill their service in terms of load bearing after just 35 years of use. [25]

What can be used instead of cement based concrete?

Concrete as a kind of fluid stone has found use in all fields of construction. But is it always necessary to use concrete? There are new materials and also tried and trusted methods of building which have mostly been replaced by concrete solutions. The replacement of conventional portland cement based concrete can cut greenhouse gas emissions and other environmental impacts significantly. Basically there are two main ways to avoid a humongous use of classic portland cement based concrete. The first one is to substitute or avoid the most polluting ingredient of classic concrete, portland cement. In a second scenario different building approaches with alternating materials or other building techniques can be applied.

Cement substitutes

First of all, portland cement based concrete mostly can be substituted by pulverized fly ash (PFA), which is a side product of coal burning processes. Another substitute with a big potential is Ground Granulated Blast-furnace Slag (GGBS), which is able to replace portland cement up to 90%. GGBS substituted concrete sets more slowly than concrete made with ordinary portland cement. The higher the amount of GGBS in the cement mix the longer it takes to cure. Besides this, a positive side effect of using GGBS substituted concrete is that it continues to gain strength over a longer period leading to improved overall durability and life expectancy. [26] Nevertheless the mentioned substitutes are by-products of other industries, such as coal, steel or aluminium production, which also have an enormous negative impact on our environment.

Green concrete

During the last decade several scientists started working on green alternatives for concrete. The most advanced approaches use micro organisms such as algae, bacteria or fungi for biocement production (CaCO3) by using the metabolic activity of these microorganisms. [27,28] Some of these bioproducts achieve similar specifics as classic portland cement and present a feasible and viable alternative to conventional portland cement based concrete.

lternative construction methods

Besides an ingredient-related replacement of conventional concrete, there are many tried and trusted construction methods which were applied in vernacular building styles and local architecture traditions. There is no convincing evidence that justifies concrete as the ultimate building material for most building tasks.

This table aims to present a series of more ecologically friendly solutions for common uses of cement concrete:

construction elementclassic building material

to be replaced / substitutedeco friendly alternative (not exhaustive)foundationsreinforced concretetyre foundation (for point foundations) [29]

gabion foundations [30]pillarsreinforced concrete

steelwooden constructions (bamboo, pine, GLT – glue laminated timber)

cardboard tubeswalls(reinforced) concrete

bricks

steel sandwich panelswooden constructions (CLT – cross laminated timber, framework constructions)

rammed earth (clay)

hempcrete

bricksflooringcement based screedclay

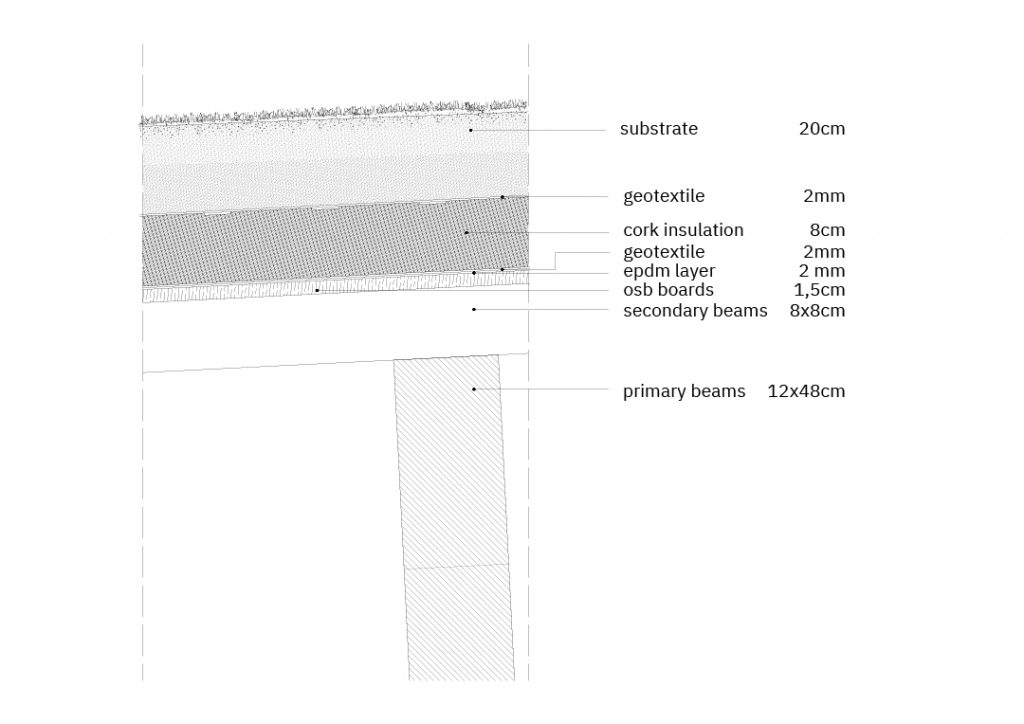

wooden planks roofsreinforced concrete (flat roofs)

steel sandwich panelswooden constructions

thatched roofs

green roofs

hempcretepathingcement based pavement

asphaltnatural stone :

cobblestone, granite plastergypsum based plaster

cement based plastercardboard + lime plaster [31]

hempcrete plaster

straw clay based plaster

Conclusion

Concrete plays a major role in building industries. The further development of newly industrializing economies with huge demands on concrete are driving the ongoing trend of a growing concrete industry. Beside its advantages and big popularity, concrete brings a lot of negative impacts on global warming, environmental systems, building culture and social city development. It is important to mention that concrete lacks recyclability. The present system around the concrete industry can be summed up as a cradle-to-grave system. Resources are extracted, used and then wasted and dumped or downcycled in the best case scenario. Due to the chemical process, cement, the most important ingredient of conventional concrete, will never be recyclable, which underlines the unsustainability of a whole industry. Its fast and wide availability and low costs in production make it popular for many large scale projects.

Nevertheless there are recent approaches to develop more sustainable alternatives to the classic portland cement-based concrete by trying to avoid or minimize the use of cementitious components, aiming for a better reusability and recyclability of resources.

In addition, investigating forgotten vernacular solutions reopens fields of research to move forward to a more environmentally respectful architecture. Stay tuned on our continuous research, on social media and if you can and feel like supporting the initiative, make a small donation on our Patreon!

Sources

[1] https://www.sciencedirect.com/science/article/pii/B978008034720250023X , opened 12.08.2020

[2] https://www.britannica.com/technology/cement-building-material/Extraction-and-processing , opened 12.08.2020

[3] https://www.screedscientist.com/portland-cement-a-brief-history/ , opened 18.08.2020

[4] Quantitative Analysis of CO2 Uptake and Mechanical … – MDPIwww.mdpi.com › pdf , opened 23.09.2020

[5] https://diglib.tugraz.at/download.php?id=576a7195cc9f9&location=browse , opened 11.08.2020

[6] 372R-13 Guide to Design and Construction of Circular Wire-and-Strand-Wrapped Prestressed Concrete Structures , 2013

[7] Historic Concrete in Scotland Part 1: history and Developmentpub-prod-sdk.azurewebsites.net › api , opened 13.08.2020

[8] https://www.britannica.com/biography/Joseph-Monier , opened 13.08.2020

[9] https://www.architectureanddesign.com.au/features/list/a-look-at-brutalist-architecture , opened 20.08.2020

[10] http://ecosmartconcrete.com/?page_id=208 , opened 12.08.2020

[11] https://global-recycling.info/pdf/GLOBAL-RECYCLING_2-2019 , opened 11.08.2020

[12] https://www.marshalls.co.uk/gardens-and-driveways/blog/how-to-mix-cement-to-make-mortar-or-concrete

[13] https://diglib.tugraz.at/download.php?id=576a7195cc9f9&location=browse , opened 26.07.2020

[14] https://global-recycling.info/pdf/GLOBAL-RECYCLING_2-2019 , opened 11.08.2020

[15] http://ecosmartconcrete.com/?page_id=208 , opened 12.08.2020

[16] http://ecosmartconcrete.com/?page_id=208 , opened 13.08.2020[1] http://ecosmartconcrete.com/?page_id=208 , opened 13.08.2020

[17] https://www.globalconstructionreview.com/news/shifting-sands-concrete-hungry-singapore-orders-mi/ , opened 28.07.2020

[18] https://www.bbc.com/worklife/article/20160502-even-desert-city-dubai-imports-its-sand-this-is-why , opened 19.08.2020

[19] https://www.bbc.com/worklife/article/20160502-even-desert-city-dubai-imports-its-sand-this-is-why , opened 19.08.2020

[20] https://www.nature.com/articles/s41893-017-0009-5.epdf , opened 26.07.2020

[21] https://www.globalconstructionreview.com/news/shifting-sands-concrete-hungry-singapore-orders-mi/ , opened 29.07.2020

[22] CSI-RecyclingConcrete-FullReport.pdf , opened 29.07.2020

[23] https://www.archdaily.com/933616/is-it-possible-to-recycle-concrete, opened 30.07.2020

[24] https://eu-recycling.com/Archive/22163 , opened 30.07.2020

[25] https://www.structuremag.org/?p=9459 , opened 18.08.2020

[26] https://www.greenspec.co.uk/building-design/concrete-cement-substitutes/ , opened 25.08.2020

[27] https://www.mdpi.com/2071-1050/10/11/4079#abstract , opened 25.08.2020

[28] https://www.sciencedirect.com/science/article/pii/S2215017X18302923 , opened 25.08.2020

[29] https://criticalconcrete.com/tyre-foundations/ , opened 25.08.2020

[30] http://bristolgreenhouse.co.uk/site/foundations.html , opened 25.08.2020

[31] https://criticalconcrete.com/out-of-the-box-vol-3/ , opened 25.08.2020

The post The reality of concrete first appeared on Critical Concrete.

Did you miss our previous article…

https://cedarparkconcrete.org/?p=109