Let us introduce the newest addition to our production center in Porto: the compost toilet! Although human waste is a taboo subject, we will be talking about poop a lot in this article. After all, if you refuse to address a topic, how can you challenge the conventional and unsustainable systems that surround it?

One unsustainable aspect of conventional toilets is water. Most toilets in wealthy countries use potable water to flush toilets, but water is a resource that is becoming scarce amid rising global temperatures. [1] [2] Even if this were not the case, the fact we contaminate drinking water on purpose reflects a dire need to challenge this convention. Human excrement, ironically, is a valuable resource. It can be used as a source of food for bacteria. Sewage, as well as diseases linked with fecal contamination of the environment, can be eliminated when composting is adopted as a sanitation method.[9]

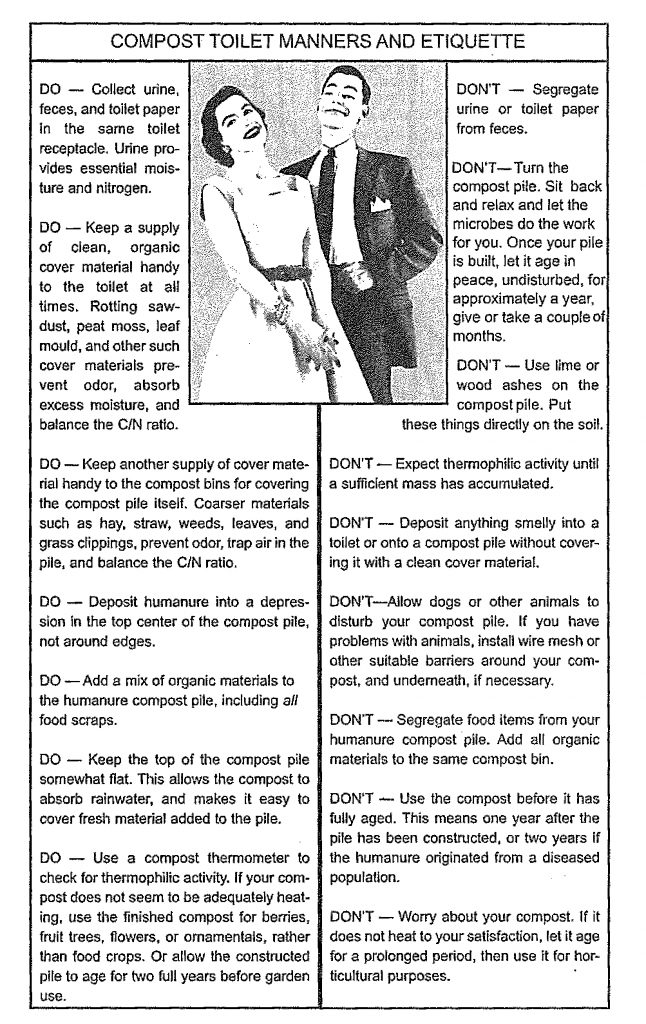

In our phytodepuration article, we explored one alternative method for wastewater treatment. It consists of a marsh-like condition, in which greywater and blackwater are filtered and purified using plants. Compost toilets are the inverse; they require no water and use dead plants rather than living ones. Essentially, microbes break the waste down into humus, a completely decomposed organic material. Besides feces, the other necessary ingredients for composting are straw, sawdust, dead leaves, or wood chips. These carbon-rich materials are known in the composting world as “browns,” while the nitrogen-rich feces make up “The Greens.” The balance of browns and greens is crucial to successful decomposition; a composting toilet without carbon-rich material would not result in compost and would be a health hazard. Additionally, the browns act as a cover material to expunge smells.

Across the world, different prototypes of compost toilets are being tested within diverse capacities and contexts. One such example is the project Mobile Dry Diversion Toilet in Lagos developed by FABULOUS URBAN with several partners since 2017. The project targets families in low-income communities who do not have access to domestic sanitation. This prototype separates the urine and feces into different compartments, which finally facilitates the process of composting. [4] The urea present in urine degrades into ammonia while not only has an off putting smell but also is the reason for the extermination of the bacteria that would otherwise break down the waste.[5] For further explanation, you may follow the link to the original article. Mobile Dry Diversion Toilet

Mock-up prototype being constructed to be tested for the project Mobile Dry Diversion Toilet Photo. © FABULOUS URBAN

Public acceptance, regulations, and a lack of expertise and experience in composting toilet design and operation are all obstacles to the use of composting toilets in urban environments [3].

We have been testing our system here at the Critical Concrete office.

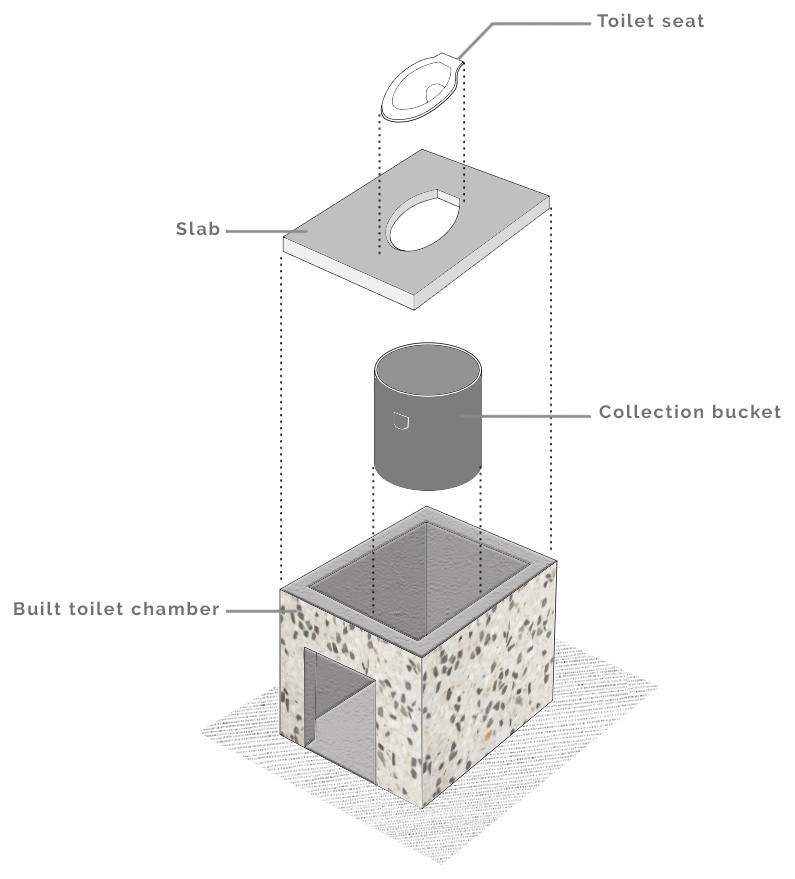

COMPONENTS OF OUR SYSTEM INCLUDE:

a large compost pilea toilet chambera bucket within the chambera seat for the chamber

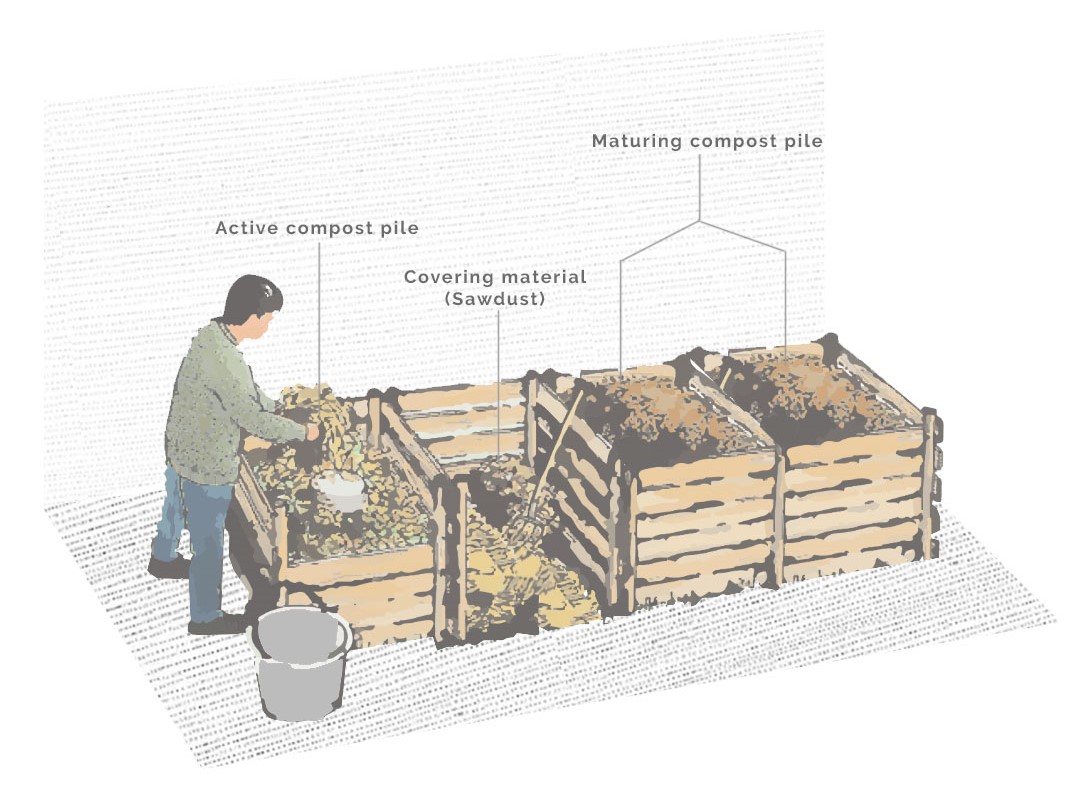

The assembly of components of the our compost toiletTo use the compost toilet, users cover their poop with a layer of carbon-rich material. In our case, this is mostly sawdust because it is a waste material that we always have on hand. Once the collection bucket in the toilet is full, we empty it into the outdoor compost pile dedicated solely to the compost toilet. The fresh layer of waste is covered with more sawdust, which immediately removes the smell and wards away flies. We then rinse the bucket, pour the rinsing water on the compost pile to help moisten the compost pile, and cover the compost pile again with fresh sawdust.

Our compost pile setup

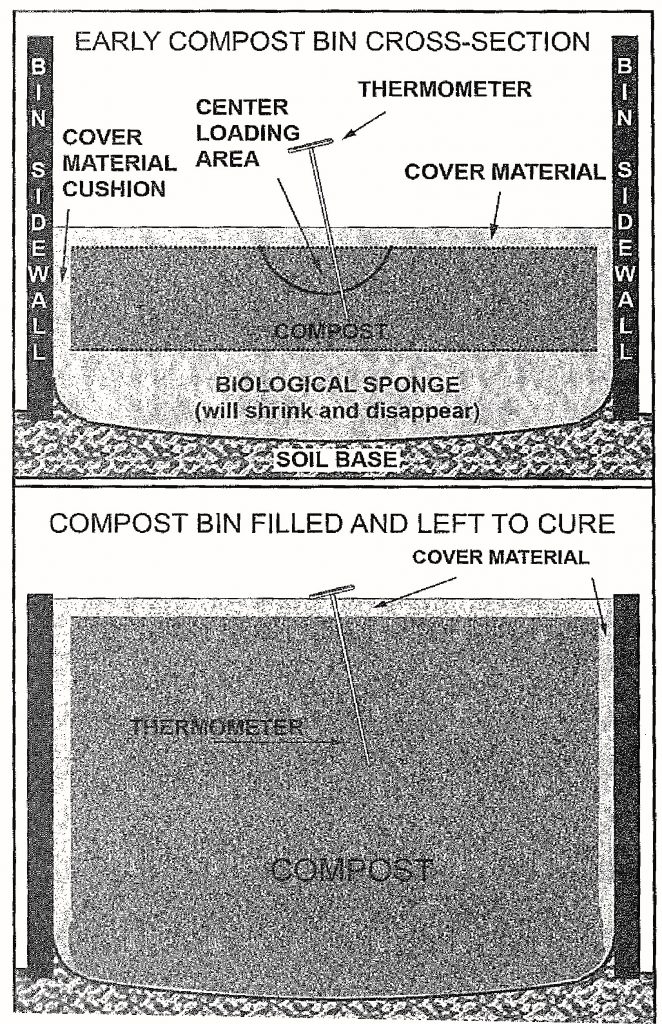

We use our compost primarily for feces as we are an office which means the usage of this toilet for urine will be more than feces. The imbalance of the proportion of urine and feces could result in a slower composting process. A low level of urine is not an issue for the decomposition, but with our compost pile located near our living space, we want to avoid the smell that it can cause. In the active compost pile, the waste completes its conversion into humus. The temperature at the core of the active compost pile can reach upto approximately 650C. The covering material such as saw dust, hay, weeds, straw is referred as biological sponge in the figure on the right. Once the compost pile is high enough, we leave it to cure for oneyear, after which it is safe to use for gardening. The curing time for compost containing human waste is longer than most compost piles, but it ensures the extermination of pathogens present in the feces before its use.

Section through the compost pile © The Humanure Handbook: shit in a nutshell

Temperature reading from our active compost pile

Making a functional compost toilet can be challenging, so of course, we had to manage some difficulties. First, the volume of our waste output is disproportionate to our available yard space. After just three months of using the toilet, the compost pile is half-full. Since the active compost pile still needs to be cured once it is ample, we may have to pause our use of the compost toilet at that point. If we had unlimited space in our yard, we would have had the chance to start a new compost pile. But in an urban setting like ours, that is not an option. Our second challenge is that our active compost pile is dry because we use a lot of sawdust. In order to create a hospitable environment for the suitable bacteria to break down our waste, we need to add moisture to the pile. At this point having some levels of urine present in the compost pile would help but, we use some greywater from washing dishes instead in order to avoid washing drinking water and unpleasant smell of urine. It will be also good to mention that according to “the Humanure Handbook: shit in a nutshell” by Joseph Jenkins for a household the separating urine and feces is not necessary.[9]

Rich fertile compost

Even though there are some obstacles to using a compost toilet, especially in an urban environment, the system is quite simple overall. For us, it is a way to transition from relying on a flush toilet and better our water usage while producing garden material. We will update our progress on this blog and our social media as we adapt to this new and improved option for human waste management in our headquarters.

Do’s and Don’ts © The Humanure Handbook: shit in a nutshell

Bibliography

[1] United Nations, “Scarcity | UN-Water,” UN-Water, 2011. https://www.unwater.org/water-facts/scarcity/.

[2] E. Saner, “The no-flush movement: the unexpected rise of the composting toilet,” The Guardian, Dec. 09, 2019.

[3] C. K. Anand and D. S. Apul, “Composting toilets as a sustainable alternative to urban sanitation – A review,” Waste Management, vol. 34, no. 2, pp. 329–343, Feb. 2014, doi: 10.1016/j.wasman.2013.10.006.

[4] “Mobile Dry Diversion Toilet FABULOUS URBAN,” Swiss-Architects. https://www.swiss-architects.com/en/fabulous-urban-zurich/project/mobile-dry-diversion-toilet?nonav=1 (accessed Oct. 06, 2021).

[5] N. Rogers, “Composting toilets could be the way of the future,” ABC News, Jun. 24, 2019.

[6] T. Avellán, “The world needs more toilets – but not ones that flush,” The Conversation, Mar. 21, 2017. https://theconversation.com/the-world-needs-more-toilets-but-not-ones-that-flush-74007 (accessed Oct. 07, 2021).

[7] “Saving water in the home,” nidirect, Oct. 20, 2015. https://www.nidirect.gov.uk/articles/saving-water-home.

[8] N. Hancock, “Safe Drinking Water Foundation,” Safe Drinking Water Foundation, Nov. 30, 2016. https://www.safewater.org/fact-sheets-1/2017/1/23/water-consumption.

[9] J. C. Jenkins, HUMANURE HANDBOOK : shit in a nutshell. S.L.: Chelsea Green, 2019.

The post Compost Toilet : Our response to water scarcity? appeared first on Critical Concrete.